Clinkers

Cement Clinker is a crucial component of Ordinary Portland Cement (OPC). Ordinary Portland Cement is made by grinding Clinker with a few other minerals.Cement Clinker is created in a rotary kiln by heating at high temperature with a homogeneous combination of raw materials in Clinker Plant. We source Clinker for the production of various grades of Cement from the world’s most competitive cement & clinker manufacturers. Our sources extend to key markets in Asia, Africa, and Europe, including Pakistan, Turkey, Vietnam, India, Indonesia, Egypt, Thailand, Oman, and the United Arab Emirates.

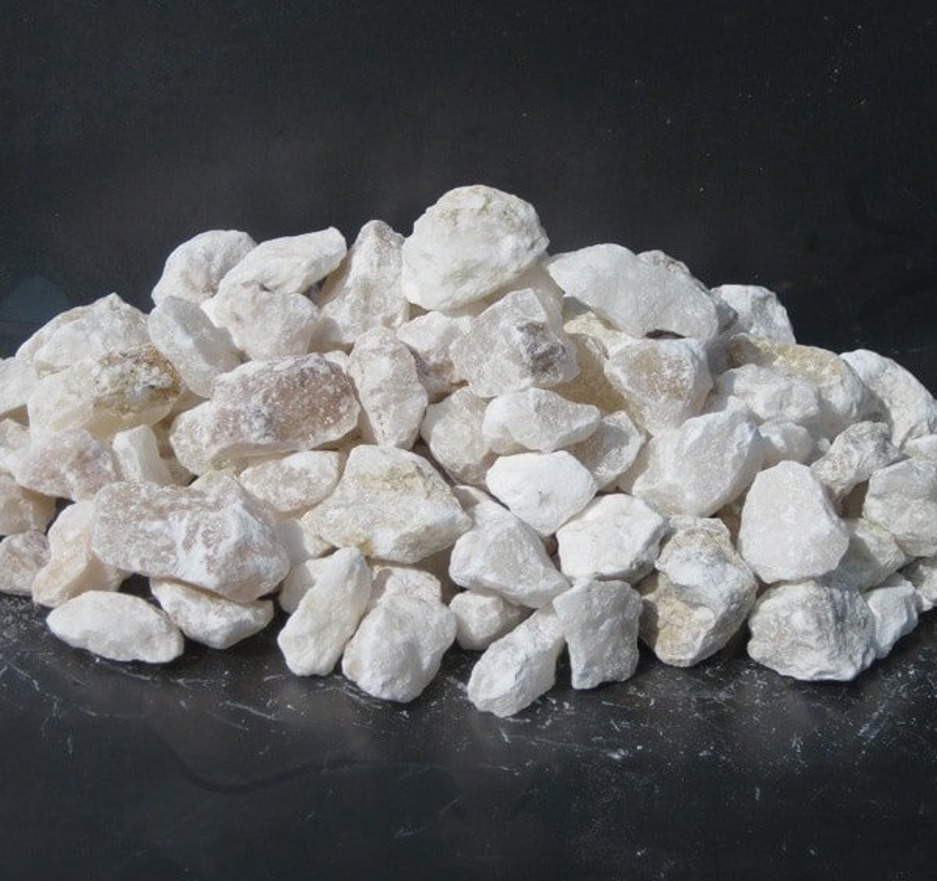

Limestone

LIMESTONE is calcareous sedimentary rock composed of the mineral calcite (CaCO3), which upon calcination yields lime (CaO) for commercial use. In its broadest interpretation the term includes any calcareous material such as marble, chalk, travertine, tufa, limeshell, coral and marl each possessing different and distinct physical properties. The crystalline equivalents of limestone having the same chemical composition are calcite and aragonite. It is extensively used in steel production, water purification, acid neutralization, making of fly ash bricks, bleaching powder formulations, agricultural purpose and chemical processing. This is highly demanded in market due to its non-toxic and eco-friendly nature, precise pH value as well as accurate composition.

Gypsum

Gypsum powder (hydrous calcium sulfate/calcium sulfate dehydrate or CaSO4-2H2O) is a white, smooth powder that is derived from heating gypsum stone. Mined gypsum is crushed, heat-dried and ground to a powder. This powder is used in various industrial, construction and agricultural applications.The gypsum powder is used as most commonly as POP to manufacture building material. As, it is soft mineral, composed of translucent crystal and have good hardening property. Gypsum is utilized as support for various molding material to form statues, sculptures, fixtures and as well as coating the walls. The craftsmen uses the gypsum powder to make beautiful and attractive idols and statues etc. It provides an unreactive surface and paints and chemicals does not react with gypsum. And, also have good lower conductivity property and used to make outer walls to keep the room cool from inside. It can be used for cement retarder, gypsum building products, model making, medical food additives, sulfuric acid production, paper filler, paint fillers.

Dolomite

Dolomite, composed of calcium and magnesium carbonate (CaCO3.MgCO3), has a theoretical composition of 45.65% MgCO3 and 54.35% CaCO3. In addition to its importance as crushed stone, it has a wide variety of industrial applications. It is used in the steelmaking industry as a flux and for manufacture of refractories for basic open hearth furnaces, Bessemer converters and steel ladles. In the cement industry it is used in refractories which line rotary cement kilns. Industrial uses of dolomite include the manufacturing of glass (the glass manufacturing industryuses pre-calcined dolomite, which theoretically contains about 21.8% magnesium oxide, MgO)

Calcium Carbonate

Calcium carbonate, or CaCO3, comprises more than 4% of the earth’s crust and is found throughout the world. Calcium carbonate, as it is used for industrial purposes, is extracted by mining or quarrying. Pure calcium carbonate can be produced from marble, or it can be prepared by passing carbon dioxide into a solution of calcium hydroxide. Calcium carbonate is the most widely used mineral in the paper, plastics, paints and coatings industries both as a filler – and due to its special white color - as a coating pigment. In the paper industry it is valued worldwide for its high brightness and light scattering characteristics, and is used as an inexpensive filler to make bright opaque paper. Filler is used at the wet-end of paper making machines, and calcium carbonate filler allows for the paper to be bright and smooth.